The world of internal combustion engines is marked by a variety of designs, each with its own set of advantages and disadvantages. Among these, the two-stroke and four-stroke engines stand out as two of the most common types, each serving distinct purposes across various applications. Understanding the fundamental differences between these engine types is crucial for anyone interested in automotive technology, marine engines, or small machinery.

Two-stroke engines complete a power cycle in just two strokes of the piston, resulting in a rapid firing rate and a lighter design. This makes them ideal for applications where weight and size are critical, such as in dirt bikes and chainsaws. However, this design often leads to higher emissions and lower fuel efficiency, making it less suitable for larger vehicles or applications with stringent environmental regulations.

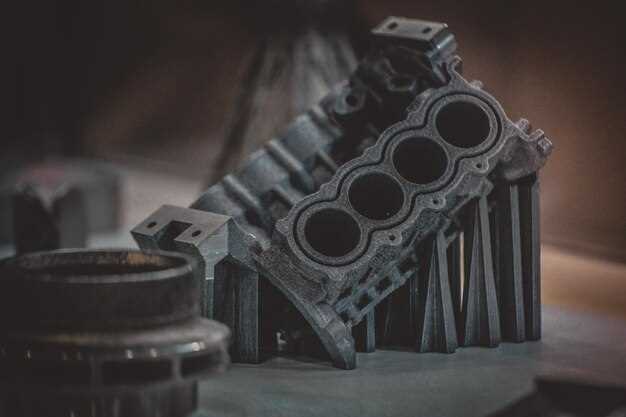

In contrast, four-stroke engines undergo four distinct strokes of the piston to complete a power cycle, leading to a more efficient fuel consumption and lower emissions. This characteristic makes four-stroke engines the preferred choice for automobiles, generators, and larger machinery, where fuel efficiency and environmental impact are significant concerns. In this comparison guide, we will delve deeper into the mechanics, performance, and application scenarios of both engine types to help you make an informed decision.

Performance Characteristics: Power Delivery and Torque Differences

When comparing two-stroke and four-stroke engines, the differences in power delivery and torque characteristics are significant. Two-stroke engines are known for their ability to produce power in a more immediate and aggressive manner. This is largely due to their design, which allows for a power stroke with every revolution of the crankshaft. As a result, two-stroke engines often have a high power-to-weight ratio, making them particularly appealing for applications requiring quick acceleration, like motocross and certain types of marine engines.

In contrast, four-stroke engines deliver power more evenly across a wider range of RPMs. The power strokes occur once every two revolutions of the crankshaft, which tends to result in smoother power delivery. This characteristic provides four-stroke engines with better overall torque management, making them more suitable for applications where consistent power over longer durations is required, such as in automobiles and larger motorcycles.

Torque levels also vary significantly between the two types of engines. Two-stroke engines typically generate higher torque at higher RPMs, resulting in a sharp, exhilarating performance. However, they may experience a fall-off in torque at lower RPMs, leading to less flexibility in lower-speed driving situations. Four-stroke engines, on the other hand, tend to produce greater torque at lower RPMs, which enhances drivability and makes them more user-friendly in various driving conditions.

In summary, the choice between a two-stroke and a four-stroke engine largely depends on the intended use. Two-stroke engines excel in providing instantaneous power and high RPM performance, while four-stroke engines offer smoother power delivery and better low-end torque, making them versatile across a range of applications.

Maintenance Requirements: Cost and Frequency Analysis

Two-stroke engines typically require more frequent maintenance compared to their four-stroke counterparts. This is primarily due to the design of two-stroke engines, which lack a dedicated lubrication system. Instead, oil is mixed with fuel, leading to more rapid wear and the necessity for regular upkeep. The combination of burning oil and fuel increases the frequency of necessary maintenance checks to ensure optimal performance and reliability.

In terms of cost, two-stroke engine maintenance can be less expensive on a per-visit basis, but the cumulative costs can add up due to the higher frequency of visits. Tasks such as spark plug replacement, fuel filter changes, and oil mixture adjustments need to be performed regularly. While each task may not incur a high expense, the necessity to perform them often can lead to higher overall maintenance costs compared to the less frequent servicing of four-stroke engines.

Four-stroke engines generally offer a more comprehensive lubrication system, leading to extended intervals between maintenance sessions. The oil is contained in a sump and circulated via a pump, resulting in lower wear rates and better engine longevity. Consequently, while the cost of four-stroke engine maintenance may be higher per session due to more complex servicing needs, the reduced frequency can lead to lower long-term financial commitments.

Ultimately, the maintenance requirements for two-stroke engines involve a trade-off between lower immediate costs and higher frequency needs, leading to a potentially steeper cumulative expense over time. Understanding these dynamics is crucial for users when evaluating which engine type aligns best with their maintenance preferences and budgetary constraints.

Application Suitability: Choosing the Right Engine for Your Needs

When selecting an engine type for a specific application, understanding the distinct characteristics of four-stroke and two-stroke engines is essential. Four-stroke engines are known for their efficiency and durability, making them ideal for applications requiring prolonged use and reliability.

For instance, four-stroke engines excel in automotive applications, where fuel efficiency and lower emissions are significant concerns. They operate on a cycle that allows for complete combustion, minimizing pollutants and maximizing power output per fuel unit. Additionally, these engines tend to have a longer lifespan due to their robust design, making them suitable for vehicles in daily use.

On the other hand, if the application requires a lightweight and compact engine with high power-to-weight ratio, such as in chainsaws or dirt bikes, two-stroke engines might be more suitable. However, this comes at the cost of higher emissions and fuel consumption.

For industrial applications that demand consistent power, like generators and water pumps, four-stroke engines are preferred. Their ability to deliver steady output without abrupt changes in speed or torque aligns well with such needs.

Ultimately, the choice between a four-stroke and a two-stroke engine depends on the specific requirements of the application, including factors such as efficiency, power delivery, and environmental considerations. Careful evaluation of these criteria can significantly enhance performance and operational efficiency.